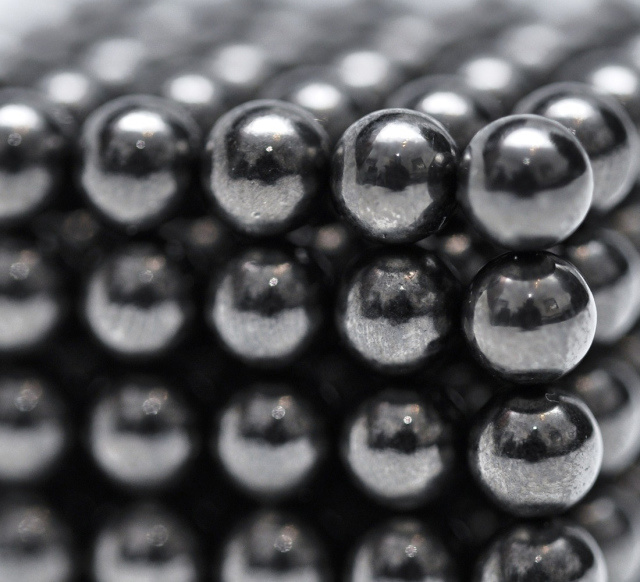

The pure tin balls produced by our company have high purity and strict control over impurity content. Uniformly organized, with fine grains, no defects, clean surface, no pollution, able to withstand high-density current operation and uniform consumption. Widely used in electronic industry welding, hardware electroplating, semiconductor, electronic products and other industries for electroplating tin. The product meets the requirements of Japanese industrial standard JIS Z3283-A and American industrial standard QQS 571E.

View more

Using fully automatic equipment for casting, the surface of the tin balls is bright and dense, with consistent sizes, more contact area, higher current efficiency, more consistent current distribution, and lower tin precipitation. The common anode ball shapes are spherical or hemispherical, with a spherical diameter of 10-25mm. Tin balls of different sizes and special shapes can be produced according to customer requirements. A hemispherical shape is similar to a spherical shape, with half of the spherical shape and a larger contact surface.

View more

Made using advanced extrusion or casting processes, the tin plate has high purity, low oxygen content, compact structure, and less residue and slag. After electroplating, the surface of the product is bright and uniform, without blackening or metal peeling. It can withstand high current density and work with uniform consumption, greatly reducing the amount of electroplating salt. The length, width, and thickness of the product can be customized according to customer requirements.

View more

Made using advanced extrusion or casting processes, pure tin bars have high purity, low oxygen content, compact structure, less residue and slag. After electroplating, the surface of the product is bright and uniform, without blackening or metal peeling. It can withstand high current density and work with uniform consumption, greatly reducing the amount of electroplating salt. The length, width, and thickness of the product can be customized according to customer requirements.

View more

Having excellent and sturdy crystal structure, uniform corrosion, higher efficiency, less maintenance, and lower energy consumption, the surface of the electroplated product is bright and uniform, without blackening, passivation, or metal peeling. The common shapes of anode rods are hexagonal, serrated, rectangular, circular, diamond, octagonal, plum blossom, etc. We can produce anode rods with different cross-sectional shapes and lengths according to customer requirements.

View more

Tin particles have high purity, low oxygen content, compact structure, and less residue and slag. After electroplating, the surface of the product is bright and uniform, without blackening or metal peeling. It can withstand high current density and work with uniform consumption, greatly reducing the amount of electroplating salt. The length, width, and thickness of the product can be customized according to customer requirements. Widely used in electronic industry welding, hardware electroplating, semiconductor, electronic products and other industries for electroplating tin. The product meets the requirements of Japanese industrial standard JIS Z3283-A and American industrial standard QQS 571E.

View more